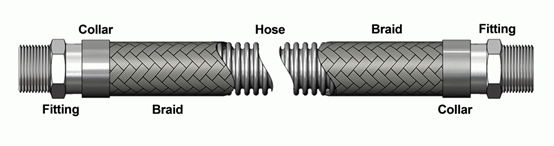

La manguera metálica flexible trenzada de alta presión SS304 tiene la ventaja de su resistencia química. -Rango de temperatura de funcionamiento de -100°C~600°C, rango de presión de 20MPA. El cuerpo de tubería corrugado cifrado puede soportar eficazmente la fuerza interna de expansión causada por la congelación a baja temperatura y tiene buena ductilidad.